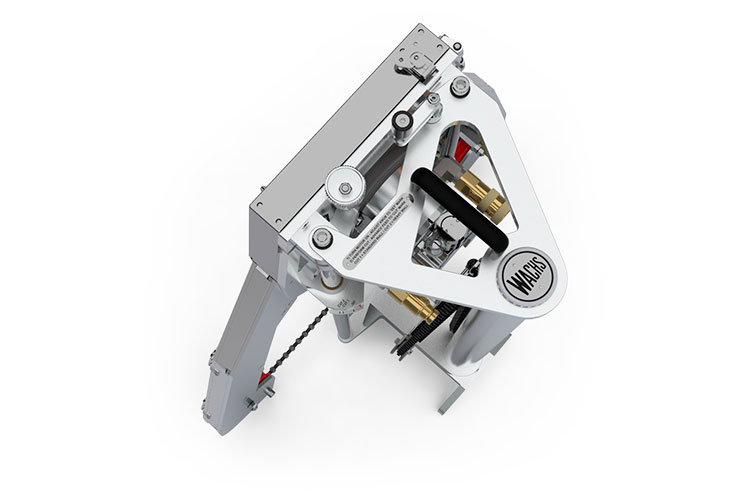

The big brother to Wachs DW Guillotine® 208 diamond wire saw, the DWG 416 is designed for cutting 4 inch to 16 inch (DN100-400) pipe including steel, ductile, cast iron, concrete (CA), poly, PVC and mixed media. The DWG 416 features exceptional build quality, with stainless steel and aluminum construction for corrosion resistance, and a collapsible, folding arm design that allows it to be easily transported and stored.

Like all Wachs cutting solutions, the DWG 416 is secured to the pipe by a quick, secure chain mounting system, eliminating the danger of kickback accidents due to binding from pipe shifting or compression cuts. Hydraulically powered using a sealed loop, the DWG 416 can operate under the most extreme conditions, including full water immersion, and is ideal for cutting in restrictive spaces.

The DWG series diamond wire is long lasting, giving the DWG 416 one of the lowest costs per cut in the industry. Like the smaller DWG 208, it utilizes a fully enclosed, high speed diamond infused cutting wire that rotates radially while cutting, allowing all the diamond elements to come into contact with the workpiece. Apart from the safety advantages, the lower cost of consumables over the life of the machine compared to handheld devices will offset its higher initial cost.

Top mounted controls for wire speed and feed allow the operator to select the optimum settings for a quick, clean cut.

DWG 416 Features

- Easy Operation and Setup

- Guillotine saw with diamond cutting power

- Cuts wide range of materials

- Reduces operator fatigue

- Less excavation required than traditional saws

- Mounts directly to the pipe

- Clean, straight cuts

- Does not bind like traditional saws

- Cuts pipe 4in-16in (DN100-400)

- Cuts Steel, Ductile, PVC and Cast Iron

Ease of Operation

- Load-sensing feature increases wire life

- Feed pressure indicator shows stress on wire during operation

- Hand grips for two person mounting

- Single person operation

- Lightweight durable construction

- User replaceable clamp contact pads and wheel inserts

- Connects directly to Wachs TM-7 or standard HPU

- Mounts vertically or horizontally

Standard Equipment

- (1) Hydraulic Diamond Wire Guillotine

- (1) High density diamond wire loop assembly

- (1) Operations manual

- (1) Spray coolant and washdown system

Optional Equipment

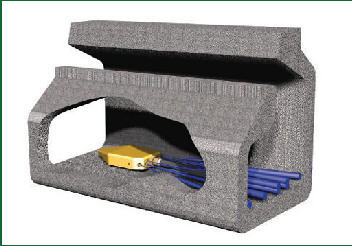

• Powder coated tube steel/stainless wheeled storage/transport carrier

• DWG 416 Carrier 29-4020-16

• Spare/replacement diamond wire loop assembly

• DWG 416 Wire 29-616-00

Specifications

Cutting Wire: Quick change continuous loop diamond wire cutting element

Hydraulic drive: HTMA class II 8 GPM @ 2000 psi (30 LPM @ 137.9 bar)

Machineable Materials: Cold cuts all pipe and bar material

Machine Capacity: 16in (DN400) width and height

Feed Rate: Variable based on workpiece material and density

Installation Method: Standard mounting chain

Controls: Single crank, manual feed; Motor on-off

Construction: Aluminum and Stainless Steel

Clamping Pads: User replaceable crush-resistant nylon clamping pads

Included Accessories: Operating manual

Finish: Natural Satin

| SPECIFICATIONS | |

| Pipe Outside Diameter Range (OD) | 4in-17.399in (101.6mm-442mm) |

| Power | |

| Application | Pipe Cutting 4″-16″ OD |

| Part Number | 29-000-16 |

| RPM | |

| Operating Dimensions | 40.75in (103.5cm) H x 12.5in (31.8cm) D x 17in (43.2cm) W Arms Folded or 31in (78.7cm) Open |

| Operating Weight | 75 lb (34kg) |

| Warranty | 1 Year Limited Warranty |