-

Formulated specifically for PVC pipelines, these wheels work well in all slippery pipes. Designed to avoid damaging the pipe wall, they utilize a granulated rubber composite which improves traction without cutting into the pipe surface. Over time they will wear, and become even more effective. If you are a contractor or city who inspects new PVC or pipe with FOG (Fats, Oils, & Grease) then you need a set of our granulated rubber wheels.

Formulated specifically for PVC pipelines, these wheels work well in all slippery pipes. Designed to avoid damaging the pipe wall, they utilize a granulated rubber composite which improves traction without cutting into the pipe surface. Over time they will wear, and become even more effective. If you are a contractor or city who inspects new PVC or pipe with FOG (Fats, Oils, & Grease) then you need a set of our granulated rubber wheels. -

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels.

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels. -

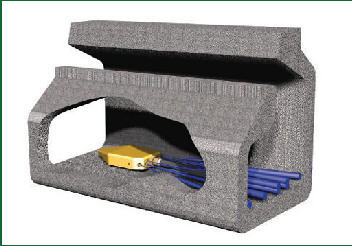

If you work in large partially-filled sanitary lines, the ARGO Camera Raft is the perfect accessory for you. Designed specifically for your RapidView IBAK system and formed out of high-strength ABS plastic, the ARGO keeps you above water and protects the camera system. There are two camera mounts to choose from. You can use a mounting bracket which accepts a standard KKD Adapter or a larger mount which accepts the standard Camera Base Mount from a T76/T86, allowing you to use a light ring.

If you work in large partially-filled sanitary lines, the ARGO Camera Raft is the perfect accessory for you. Designed specifically for your RapidView IBAK system and formed out of high-strength ABS plastic, the ARGO keeps you above water and protects the camera system. There are two camera mounts to choose from. You can use a mounting bracket which accepts a standard KKD Adapter or a larger mount which accepts the standard Camera Base Mount from a T76/T86, allowing you to use a light ring. -

In dry pipes, the Laser Profiler system allows you to get extremely accurate pipeline measurements. The system projects a laser ring on the pipe wall which is recorded for data analysis. A sophisticated suite of software tools are available to work with the data you capture to give you exactly what you need. This tool is perfect for testing deflection or erosion in new and old pipes.

In dry pipes, the Laser Profiler system allows you to get extremely accurate pipeline measurements. The system projects a laser ring on the pipe wall which is recorded for data analysis. A sophisticated suite of software tools are available to work with the data you capture to give you exactly what you need. This tool is perfect for testing deflection or erosion in new and old pipes. -

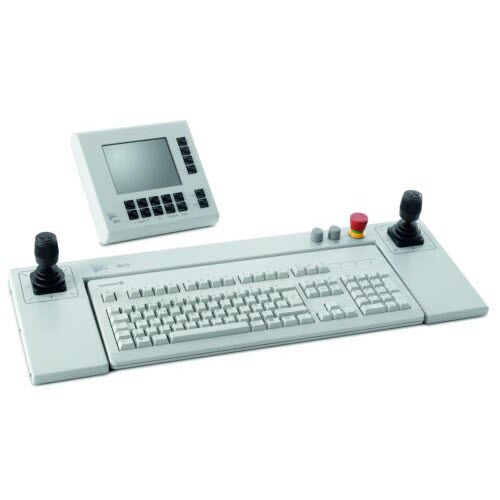

The BS 10 was developed for vehicle mounted installations of the compact KW 206 and KW 306 cable drums. These drums contain the power supply requirements of the down-hole equipment, and therefore the controller itself can be slimmer, lighter, and hidden from view. This controller includes an interface cable between the drum and the required computer. The desk component of the BS 10 is a keyboard surround with ergonomic joysticks, power on/off, microphone and 6 quick-keys for present controls.

The BS 10 was developed for vehicle mounted installations of the compact KW 206 and KW 306 cable drums. These drums contain the power supply requirements of the down-hole equipment, and therefore the controller itself can be slimmer, lighter, and hidden from view. This controller includes an interface cable between the drum and the required computer. The desk component of the BS 10 is a keyboard surround with ergonomic joysticks, power on/off, microphone and 6 quick-keys for present controls. -

Our most powerful fiber optic control unit is the BS 5.0. The BS 5.0 controller utilizes a unique remote control panel that can be positioned on your workspace and can control any piece of equipment easily and quickly. The BS 5.0 controller is the only control system capable of performing mainline inspection lengths of up to 2000′ (600m). If you need the greatest inspection distance and the brightest lighting, the BS 5.0 is your number one choice!

Our most powerful fiber optic control unit is the BS 5.0. The BS 5.0 controller utilizes a unique remote control panel that can be positioned on your workspace and can control any piece of equipment easily and quickly. The BS 5.0 controller is the only control system capable of performing mainline inspection lengths of up to 2000′ (600m). If you need the greatest inspection distance and the brightest lighting, the BS 5.0 is your number one choice! -

The BS 7.0 is the standard fiber optic mainline control unit, supporting High Definition cables and optic camera systems. Matching the same shape as its sibling the BS 3.5, these controllers feature a small main unit that is easily mountable under the desk or in any electronic control rack. The remote control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks. The BS 7.0 controller is the standard fiber optic controller. This controller functions exactly like the BS 3.5 controller, but includes larger power supplies and supports mainline fiber optic systems like PANORAMO and PANORAMO SI.

The BS 7.0 is the standard fiber optic mainline control unit, supporting High Definition cables and optic camera systems. Matching the same shape as its sibling the BS 3.5, these controllers feature a small main unit that is easily mountable under the desk or in any electronic control rack. The remote control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks. The BS 7.0 controller is the standard fiber optic controller. This controller functions exactly like the BS 3.5 controller, but includes larger power supplies and supports mainline fiber optic systems like PANORAMO and PANORAMO SI. -

The BS 3.5 control unit is the standard in ergonomic controller design. The remote-control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks making mainline inspections a breeze.

The BS 3.5 control unit is the standard in ergonomic controller design. The remote-control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks making mainline inspections a breeze. -

The BP1 control unit is equipped with a 10-inch touchscreen display and is optimally suited to control the MicroLite Push System. Pan and tilt cameras can be controlled by the BP1.

The BP1 control unit is equipped with a 10-inch touchscreen display and is optimally suited to control the MicroLite Push System. Pan and tilt cameras can be controlled by the BP1.