Utility Pipe Saws and Cutters

Wachs portable pipe saws and cutters are the safest and most dependable in the industry, and are designed to cold cut steel, ductile, cast iron and most common pipe types. Products in the line include our famous Trav-L-Cutter, newly updated to SD Super Duty specification with new heavy duty internal components. Secured to the pipe by a special tensioning/drive/mounting chain, the Trav-L-Cutter SD drives itself around the pipe as it cuts. It’s designed for severing and beveling all common pipe materials, wall thicknesses and sizes from 6 inch O.D. (DN150) on up.

Another industry standard is our reciprocating Wachs Guillotine Saw, sometimes called simply the “Wachs Saw”. The family of portable Guillotine pipe saws include models designed to cold cut pipe ranging from 2 inch – 32 inch (DN50-800), anywhere a fast, safe cut is needed. In use virtually everywhere, they’re strong yet lightweight, simple to mount, simple to operate and simply bulletproof.

Our newest innovation is our DW (Diamond Wire) Guillotine saws, available in two models with two different size ranges, the DWG 208 and DWG 416. Wachs Diamond Wire Guillotine pipe saws are just one example of safety and efficiency driving our product design. These compact saws utilize top mounted controls, and a diamond infused cutting wire to cut 2 inch to 8 inch pipe (DWG 208) and 4 inch to 16 inch pipe (DWG 416). Unlike traditional gas powered handheld chop and chain saws, these secure to the workpiece, eliminating the danger of power saw “kickback” injuries, a huge safety benefit.

-

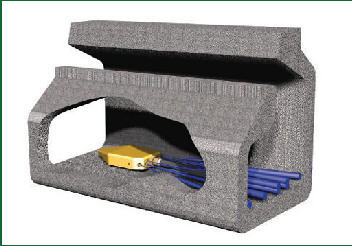

Wachs DW Guillotine® 208 Diamond Wire pipe saw is a faster and safer method of cutting 2 inch to 8 inch (DN50-200) pipe including steel, ductile, cast iron, concrete (CA), poly, PVC and mixed media. Secured to the pipe, the DWG 208 utilizes a fully enclosed, high speed diamond infused cutting wire that cuts quickly and precisely. Its compact design features stainless steel construction, with a collapsible, folding arm design that allows it to be easily stored and transported. Every DWG 208 saw comes complete with a custom carrier for protection, plus a carrier mounted water tank and spray lubricant. These saws do not bind like traditional saws, eliminating the kickback dangers associated with gasoline powered handheld chain saws or abrasive wheel devices that can occur from pipe compression or shifting. The DWG 208 is hydraulically powered using a sealed loop that can run in water, eliminating the danger of gas fumes collecting when working down in the ground. Apart from the cutting area, the diamond wire is fully enclosed within the saw for safety. The diamond wire is designed to slightly rotate radially while cutting, allowing all the diamond elements to come into contact with the workpiece. Due to the longevity of the diamond cutting wire Wachs DW series saws feature one of the lowest costs per cut in the industry, and a much lower cost of consumables over the life of the machine than other cutting devices.

Wachs DW Guillotine® 208 Diamond Wire pipe saw is a faster and safer method of cutting 2 inch to 8 inch (DN50-200) pipe including steel, ductile, cast iron, concrete (CA), poly, PVC and mixed media. Secured to the pipe, the DWG 208 utilizes a fully enclosed, high speed diamond infused cutting wire that cuts quickly and precisely. Its compact design features stainless steel construction, with a collapsible, folding arm design that allows it to be easily stored and transported. Every DWG 208 saw comes complete with a custom carrier for protection, plus a carrier mounted water tank and spray lubricant. These saws do not bind like traditional saws, eliminating the kickback dangers associated with gasoline powered handheld chain saws or abrasive wheel devices that can occur from pipe compression or shifting. The DWG 208 is hydraulically powered using a sealed loop that can run in water, eliminating the danger of gas fumes collecting when working down in the ground. Apart from the cutting area, the diamond wire is fully enclosed within the saw for safety. The diamond wire is designed to slightly rotate radially while cutting, allowing all the diamond elements to come into contact with the workpiece. Due to the longevity of the diamond cutting wire Wachs DW series saws feature one of the lowest costs per cut in the industry, and a much lower cost of consumables over the life of the machine than other cutting devices. -

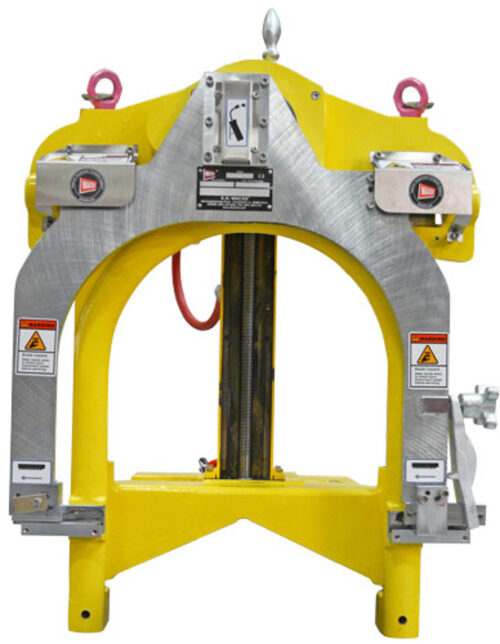

The big brother to Wachs DW Guillotine® 208 diamond wire saw, the DWG 416 is designed for cutting 4 inch to 16 inch (DN100-400) pipe including steel, ductile, cast iron, concrete (CA), poly, PVC and mixed media. The DWG 416 features exceptional build quality, with stainless steel and aluminum construction for corrosion resistance, and a collapsible, folding arm design that allows it to be easily transported and stored. Like all Wachs cutting solutions, the DWG 416 is secured to the pipe by a quick, secure chain mounting system, eliminating the danger of kickback accidents due to binding from pipe shifting or compression cuts. Hydraulically powered using a sealed loop, the DWG 416 can operate under the most extreme conditions, including full water immersion, and is ideal for cutting in restrictive spaces. The DWG series diamond wire is long lasting, giving the DWG 416 one of the lowest costs per cut in the industry. Like the smaller DWG 208, it utilizes a fully enclosed, high speed diamond infused cutting wire that rotates radially while cutting, allowing all the diamond elements to come into contact with the workpiece. Apart from the safety advantages, the lower cost of consumables over the life of the machine compared to handheld devices will offset its higher initial cost. Top mounted controls for wire speed and feed allow the operator to select the optimum settings for a quick, clean cut.

The big brother to Wachs DW Guillotine® 208 diamond wire saw, the DWG 416 is designed for cutting 4 inch to 16 inch (DN100-400) pipe including steel, ductile, cast iron, concrete (CA), poly, PVC and mixed media. The DWG 416 features exceptional build quality, with stainless steel and aluminum construction for corrosion resistance, and a collapsible, folding arm design that allows it to be easily transported and stored. Like all Wachs cutting solutions, the DWG 416 is secured to the pipe by a quick, secure chain mounting system, eliminating the danger of kickback accidents due to binding from pipe shifting or compression cuts. Hydraulically powered using a sealed loop, the DWG 416 can operate under the most extreme conditions, including full water immersion, and is ideal for cutting in restrictive spaces. The DWG series diamond wire is long lasting, giving the DWG 416 one of the lowest costs per cut in the industry. Like the smaller DWG 208, it utilizes a fully enclosed, high speed diamond infused cutting wire that rotates radially while cutting, allowing all the diamond elements to come into contact with the workpiece. Apart from the safety advantages, the lower cost of consumables over the life of the machine compared to handheld devices will offset its higher initial cost. Top mounted controls for wire speed and feed allow the operator to select the optimum settings for a quick, clean cut. -

Model D pneumatic drive reciprocating pipe saw designed to cut solids, multi-stranded casing strings and nested materials from 6in-18in (DN150-450 or 15cm-46cm) or up to 16in (DN400 or 41cm) on ductile pipe, with a choice of horizontal or vertical mounting. Includes:

Model D pneumatic drive reciprocating pipe saw designed to cut solids, multi-stranded casing strings and nested materials from 6in-18in (DN150-450 or 15cm-46cm) or up to 16in (DN400 or 41cm) on ductile pipe, with a choice of horizontal or vertical mounting. Includes:- air motor

- blade

- operating hand tools

- manual