-

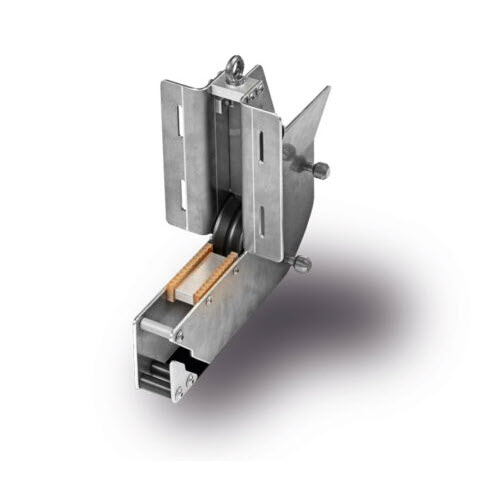

IBAK has developed a new, affordable solution that is ideal for service providers seeking the benefits of having both a compact cutting system, as well as a complete inspection system. Look no further than the IBAK MicroGator® Air, a pneumatic cutter designed with compatibility and convenience in mind. Equipped with a 1.5 horsepower pneumatic motor and manufactured to IBAK’s exacting quality standards, the MicroGator® Air is a practical, yet reliable solution. One feature that makes this cutter unique is its focus on modularity. The MicroGator® Air is compatible with the components to our MainLite Systems including the KW206 and KW306 cable reels, our BP100 and BS10 control units, and even the same cable. With these components, all you need is a hose reel for the air hose and a compressor to have a complete cutting system. The MicroGator® Air shares many of the same features as the MicroGator® 2.0, such as fourth-axis articulation, which allows the user ultimate control during advanced cutting operations. The IBAK CutterCam is compatible with the MicroGator® Air and provides the best possible view of the cutting area. Even if it gets dirty, our unique air-curtain technology and remote wiper system will keep your camera lens clean with the push of a button.

IBAK has developed a new, affordable solution that is ideal for service providers seeking the benefits of having both a compact cutting system, as well as a complete inspection system. Look no further than the IBAK MicroGator® Air, a pneumatic cutter designed with compatibility and convenience in mind. Equipped with a 1.5 horsepower pneumatic motor and manufactured to IBAK’s exacting quality standards, the MicroGator® Air is a practical, yet reliable solution. One feature that makes this cutter unique is its focus on modularity. The MicroGator® Air is compatible with the components to our MainLite Systems including the KW206 and KW306 cable reels, our BP100 and BS10 control units, and even the same cable. With these components, all you need is a hose reel for the air hose and a compressor to have a complete cutting system. The MicroGator® Air shares many of the same features as the MicroGator® 2.0, such as fourth-axis articulation, which allows the user ultimate control during advanced cutting operations. The IBAK CutterCam is compatible with the MicroGator® Air and provides the best possible view of the cutting area. Even if it gets dirty, our unique air-curtain technology and remote wiper system will keep your camera lens clean with the push of a button. -

Introducing the most advanced cutting and grinding robot on the market today! The MicroGATOR® 2.0 is the powerful, single-point electric reinstatement cutter and grinder manufactured to the exacting quality standards of IBAK. With longer cable lengths, powerful and quiet cutting motors, and drive units designed to withstand the toughest jobs, these cutters have already reset the industry’s expectations. High powered cutting motors are deployed from the durable cutter chassis. The main body expands to center the tool in the pipeline and the on-board monitoring camera ensures that you can operate the unit with ease. You can even make 360° cuts! MicroGator 2.0 in Action: 🎦 Cutting PVC in Real Time 🎦 Finding & Cutting Missed Tap 🎦 Cutting Protruding Taps & Roots 🎦 Cutting Out A Liner 🎦 Cutting A Lateral

Introducing the most advanced cutting and grinding robot on the market today! The MicroGATOR® 2.0 is the powerful, single-point electric reinstatement cutter and grinder manufactured to the exacting quality standards of IBAK. With longer cable lengths, powerful and quiet cutting motors, and drive units designed to withstand the toughest jobs, these cutters have already reset the industry’s expectations. High powered cutting motors are deployed from the durable cutter chassis. The main body expands to center the tool in the pipeline and the on-board monitoring camera ensures that you can operate the unit with ease. You can even make 360° cuts! MicroGator 2.0 in Action: 🎦 Cutting PVC in Real Time 🎦 Finding & Cutting Missed Tap 🎦 Cutting Protruding Taps & Roots 🎦 Cutting Out A Liner 🎦 Cutting A Lateral -

This attachment allows you to turn your LISY lateral launch system into a lateral cleaning unit. The PHOBOS nozzle propels the pushrod up into the lateral from the LISY unit, cleaning while it goes. The nozzle not only cleans, but increases the distance possible by providing more thrust. The lateral cleaning attachment is quick and easy to install, and can be used in conjunction with the large diameter kits to clean laterals in larger pipelines. If you are a contractor, you can use this accessory to add a unique service to your offering. If you are a municipality who is responsible for the laterals in your community, why not clean them as you inspect?

This attachment allows you to turn your LISY lateral launch system into a lateral cleaning unit. The PHOBOS nozzle propels the pushrod up into the lateral from the LISY unit, cleaning while it goes. The nozzle not only cleans, but increases the distance possible by providing more thrust. The lateral cleaning attachment is quick and easy to install, and can be used in conjunction with the large diameter kits to clean laterals in larger pipelines. If you are a contractor, you can use this accessory to add a unique service to your offering. If you are a municipality who is responsible for the laterals in your community, why not clean them as you inspect? -

Operators who protect their equipment with the use of Downhole Rollers will see an increase in production and an overall reduction of repairs and maintenance costs. Rollers protect the cable from cuts, reduce friction, wick water off the cable and increase the distance your system can travel down the pipeline. You wouldn’t buy a high performance car then put cheap tires on it, would you? Of course not! Protect your investment with a set of downhole rollers.

Operators who protect their equipment with the use of Downhole Rollers will see an increase in production and an overall reduction of repairs and maintenance costs. Rollers protect the cable from cuts, reduce friction, wick water off the cable and increase the distance your system can travel down the pipeline. You wouldn’t buy a high performance car then put cheap tires on it, would you? Of course not! Protect your investment with a set of downhole rollers. -

If you occasionally have to set up off the road or any distance from the inspection vehicle, you simply must have an upper deflection pulley. This pulley converts the lateral force exerted onto the cable, turning into vertical force which allows your synchronized KW 305 or KW 505 to operate effectively. This simple attachment protects the cable, reduces the strain on the entire system, and helps you travel greater distances in the pipeline!

If you occasionally have to set up off the road or any distance from the inspection vehicle, you simply must have an upper deflection pulley. This pulley converts the lateral force exerted onto the cable, turning into vertical force which allows your synchronized KW 305 or KW 505 to operate effectively. This simple attachment protects the cable, reduces the strain on the entire system, and helps you travel greater distances in the pipeline! -

Manned-entry inspections are challenging, but occasionally necessary. The CERBERUS camera allows you to conduct these inspections quickly and safely using your existing drum, cable, and controller. The CERBERUS features laser measurement, zoom, and two ultra-bright LED lights. The camera cable serves as an added tether to increase safety, and bi-directional microphones keep everyone in communication. The CERBERUS will require an extension kit. Which kit you need will depend upon your specific system configuration. Please contact your RapidView representative to help choose the correct kit.

Manned-entry inspections are challenging, but occasionally necessary. The CERBERUS camera allows you to conduct these inspections quickly and safely using your existing drum, cable, and controller. The CERBERUS features laser measurement, zoom, and two ultra-bright LED lights. The camera cable serves as an added tether to increase safety, and bi-directional microphones keep everyone in communication. The CERBERUS will require an extension kit. Which kit you need will depend upon your specific system configuration. Please contact your RapidView representative to help choose the correct kit. -

Most of our systems are synchronized to make sure that you do not back over your cable while retrieving, but occasionally it is helpful to have a rear-facing view when returning to the manhole. The RETRUS HD automatically changes your view in full digital HD resolution when the system is reversed allowing you to avoid dangers on the return trip.

Most of our systems are synchronized to make sure that you do not back over your cable while retrieving, but occasionally it is helpful to have a rear-facing view when returning to the manhole. The RETRUS HD automatically changes your view in full digital HD resolution when the system is reversed allowing you to avoid dangers on the return trip. -

This large attachment adds considerable height and weight to the system. This makes sure you are up out of the water while maintaining a low center of gravity. The large attachment includes additional weight which hangs below the carriage. The large attachment is the same for both the T76 and T86 tractors, but require different mounting brackets.

This large attachment adds considerable height and weight to the system. This makes sure you are up out of the water while maintaining a low center of gravity. The large attachment includes additional weight which hangs below the carriage. The large attachment is the same for both the T76 and T86 tractors, but require different mounting brackets. -

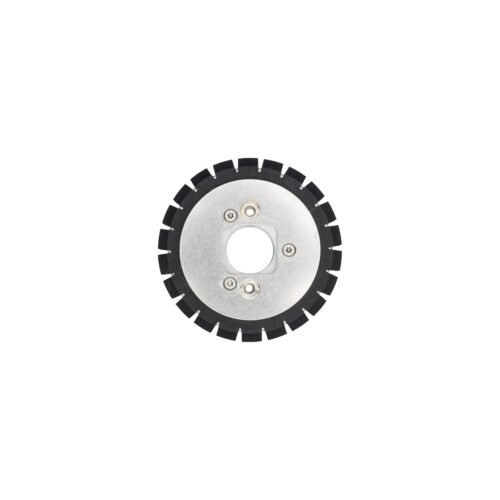

Available in two different composites, these wheels are perfect for climbing over rocks and debris. Profiled to maximize pipeline contact area, these high performance wheels provide extra grip in loose gravel and give you an edge when climbing up offset pipeline joints. Available in hard (black) or softer (brown) composites for any application.

Available in two different composites, these wheels are perfect for climbing over rocks and debris. Profiled to maximize pipeline contact area, these high performance wheels provide extra grip in loose gravel and give you an edge when climbing up offset pipeline joints. Available in hard (black) or softer (brown) composites for any application. -

Formulated specifically for PVC pipelines, these wheels work well in all slippery pipes. Designed to avoid damaging the pipe wall, they utilize a granulated rubber composite which improves traction without cutting into the pipe surface. Over time they will wear, and become even more effective. If you are a contractor or city who inspects new PVC or pipe with FOG (Fats, Oils, & Grease) then you need a set of our granulated rubber wheels.

Formulated specifically for PVC pipelines, these wheels work well in all slippery pipes. Designed to avoid damaging the pipe wall, they utilize a granulated rubber composite which improves traction without cutting into the pipe surface. Over time they will wear, and become even more effective. If you are a contractor or city who inspects new PVC or pipe with FOG (Fats, Oils, & Grease) then you need a set of our granulated rubber wheels. -

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels.

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels. -

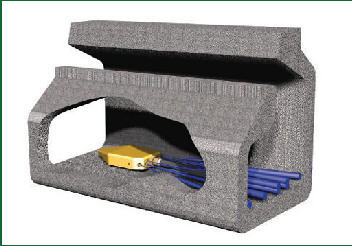

If you work in large partially-filled sanitary lines, the ARGO Camera Raft is the perfect accessory for you. Designed specifically for your RapidView IBAK system and formed out of high-strength ABS plastic, the ARGO keeps you above water and protects the camera system. There are two camera mounts to choose from. You can use a mounting bracket which accepts a standard KKD Adapter or a larger mount which accepts the standard Camera Base Mount from a T76/T86, allowing you to use a light ring.

If you work in large partially-filled sanitary lines, the ARGO Camera Raft is the perfect accessory for you. Designed specifically for your RapidView IBAK system and formed out of high-strength ABS plastic, the ARGO keeps you above water and protects the camera system. There are two camera mounts to choose from. You can use a mounting bracket which accepts a standard KKD Adapter or a larger mount which accepts the standard Camera Base Mount from a T76/T86, allowing you to use a light ring. -

In dry pipes, the Laser Profiler system allows you to get extremely accurate pipeline measurements. The system projects a laser ring on the pipe wall which is recorded for data analysis. A sophisticated suite of software tools are available to work with the data you capture to give you exactly what you need. This tool is perfect for testing deflection or erosion in new and old pipes.

In dry pipes, the Laser Profiler system allows you to get extremely accurate pipeline measurements. The system projects a laser ring on the pipe wall which is recorded for data analysis. A sophisticated suite of software tools are available to work with the data you capture to give you exactly what you need. This tool is perfect for testing deflection or erosion in new and old pipes. -

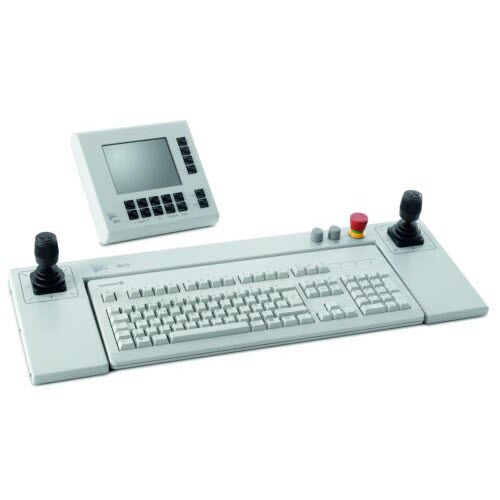

The BS 10 was developed for vehicle mounted installations of the compact KW 206 and KW 306 cable drums. These drums contain the power supply requirements of the down-hole equipment, and therefore the controller itself can be slimmer, lighter, and hidden from view. This controller includes an interface cable between the drum and the required computer. The desk component of the BS 10 is a keyboard surround with ergonomic joysticks, power on/off, microphone and 6 quick-keys for present controls.

The BS 10 was developed for vehicle mounted installations of the compact KW 206 and KW 306 cable drums. These drums contain the power supply requirements of the down-hole equipment, and therefore the controller itself can be slimmer, lighter, and hidden from view. This controller includes an interface cable between the drum and the required computer. The desk component of the BS 10 is a keyboard surround with ergonomic joysticks, power on/off, microphone and 6 quick-keys for present controls. -

Our most powerful fiber optic control unit is the BS 5.0. The BS 5.0 controller utilizes a unique remote control panel that can be positioned on your workspace and can control any piece of equipment easily and quickly. The BS 5.0 controller is the only control system capable of performing mainline inspection lengths of up to 2000′ (600m). If you need the greatest inspection distance and the brightest lighting, the BS 5.0 is your number one choice!

Our most powerful fiber optic control unit is the BS 5.0. The BS 5.0 controller utilizes a unique remote control panel that can be positioned on your workspace and can control any piece of equipment easily and quickly. The BS 5.0 controller is the only control system capable of performing mainline inspection lengths of up to 2000′ (600m). If you need the greatest inspection distance and the brightest lighting, the BS 5.0 is your number one choice! -

The BS 7.0 is the standard fiber optic mainline control unit, supporting High Definition cables and optic camera systems. Matching the same shape as its sibling the BS 3.5, these controllers feature a small main unit that is easily mountable under the desk or in any electronic control rack. The remote control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks. The BS 7.0 controller is the standard fiber optic controller. This controller functions exactly like the BS 3.5 controller, but includes larger power supplies and supports mainline fiber optic systems like PANORAMO and PANORAMO SI.

The BS 7.0 is the standard fiber optic mainline control unit, supporting High Definition cables and optic camera systems. Matching the same shape as its sibling the BS 3.5, these controllers feature a small main unit that is easily mountable under the desk or in any electronic control rack. The remote control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks. The BS 7.0 controller is the standard fiber optic controller. This controller functions exactly like the BS 3.5 controller, but includes larger power supplies and supports mainline fiber optic systems like PANORAMO and PANORAMO SI. -

The BS 3.5 control unit is the standard in ergonomic controller design. The remote-control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks making mainline inspections a breeze.

The BS 3.5 control unit is the standard in ergonomic controller design. The remote-control board acts as your diagnostic and control interface. All system functions are easily accessed by this small desktop unit. System information is displayed on a color LCD touchscreen while camera and tractor movements, focus, iris, cruise control and lateral launch commands are controlled from the dual, multi-axis joysticks making mainline inspections a breeze.