-

The Vac•Con X-Cavator EXT is designed to take on the harshest environments that operators venture into. Contractors and municipalities alike will discover that the all-new X-Cavator EXT is built to exceed their demands. The X-Cavator EXT is at home in:

The Vac•Con X-Cavator EXT is designed to take on the harshest environments that operators venture into. Contractors and municipalities alike will discover that the all-new X-Cavator EXT is built to exceed their demands. The X-Cavator EXT is at home in:- Oil & Gas Fields

- Heavy Construction Zones

- Utility Sites

- Telecommunication Sites

- Urban & Rural Terrain

- Daylighting and exposing underground utilities

- Soil trenching

- Debris removal

- Piling hole excavation

- Cold weather digging

-

The X-Cavator™ enables you to locate and safely excavate around delicate utilities without damaging them. There is no application too tough for the X-Cavator™. Order yours with specific, powerful options to handle those crucial excavation jobs like:

The X-Cavator™ enables you to locate and safely excavate around delicate utilities without damaging them. There is no application too tough for the X-Cavator™. Order yours with specific, powerful options to handle those crucial excavation jobs like:- Trenching

- Potholing/Daylighting

- Exposing underground utilities

- Water & sewer repairs

- Highway & street repairs

- Propane & gas tank remediation

- Long distance & congested area excavation

- Oil & gas distribution lines

-

WOLVERINE AUTOMATED SIDE LOADER

The New Way® Wolverine™ is the latest innovation from New Way Trucks and joins the largest and most diverse family of refuse equipment in the industry. The Wolverine has the attributes of its larger sibling, just in a smaller package. Although the Wolverine is a full-fledged collection vehicle, it is available in an under-CDL package, making finding and training new drivers considerably easier. Your new drivers can focus on safety, customer service, and a manageable route footprint in a smaller vehicle, and eventually graduate to a full-sized unit bringing those skills forward to a larger – yet still familiar – vehicle. For the last 20 years, the solid waste industry focused on improving productivity. That effort translated to bigger and fewer collection routes, larger trucks, and fleet-rightsizing. Given the current CDL driver shortage, however, one shoe does not fit all markets. Hauling operators are now seeing those trends begin to reverse. There is a willingness to expand fleets with smaller collection vehicles with hopes of expanding the labor pool and drawing candidates from groups not traditionally targeted by the nation’s waste haulers. New Way Trucks is poised and ready to meet that need. The industry’s continued shift to automation has further proven to extend an aging workforce while at the same time becoming gender neutral. Historically solid waste has been male-dominated due to the heavy lifting requirements. However, technology has solved that problem. Automation does the heavy lifting, and equipment manufacturers are designing for smaller stature, creating access to more commercial drivers in a time when driver shortages are widespread. The New Way Sidewinder XTR™ is the best-selling Class 8 automated side-loader in the industry. It’s just a matter of time before the Wolverine becomes the most sought-after Class 6. -

The VJT750 is a jetter system mounted onto a portable truck chassis, designed and built by the sewer cleaning experts you trust at Vac-Con. This unit features a simple design and operation so operators of all skill levels can master the art of jetting. A low-profile configuration offers greater safety and the structural steel frame provides one of the strongest trailers on the market. The VJT750 can be relied upon to get to the job quickly and provide the performance and power expected from Vac-Con machines.

The VJT750 is a jetter system mounted onto a portable truck chassis, designed and built by the sewer cleaning experts you trust at Vac-Con. This unit features a simple design and operation so operators of all skill levels can master the art of jetting. A low-profile configuration offers greater safety and the structural steel frame provides one of the strongest trailers on the market. The VJT750 can be relied upon to get to the job quickly and provide the performance and power expected from Vac-Con machines. -

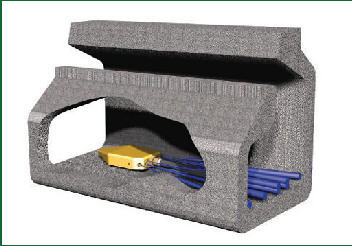

The VJT1500 is an enclosed jetter truck designed and built by the sewer cleaning experts you trust at Vac-Con. This unit offers simple operation and the most accessibility on the market with 6-ft. wide door openings on three sides. Operator ergonomics are at the forefront of this machine with a height adjustable control panel to suit all operators. The hose reel on the VJT1500 can be used outside of the enclosure even with the doors closed to keep your water system protected during extreme weather. Cold or hot, rain or shine, the VJT1500 is an operator’s go-to for pipeline cleaning and jetting.

The VJT1500 is an enclosed jetter truck designed and built by the sewer cleaning experts you trust at Vac-Con. This unit offers simple operation and the most accessibility on the market with 6-ft. wide door openings on three sides. Operator ergonomics are at the forefront of this machine with a height adjustable control panel to suit all operators. The hose reel on the VJT1500 can be used outside of the enclosure even with the doors closed to keep your water system protected during extreme weather. Cold or hot, rain or shine, the VJT1500 is an operator’s go-to for pipeline cleaning and jetting. -

The All-New Vac-Con Jetter Series VJ375 and VJ750 are designed to take on the toughest sewer lines, storm drains and catch basins in a portable trailer-mounted configuration. This new low-profile design features the same power and portability for which Vac-Con trailer-mounted units are known. Applications include sewer line, storm drain, and catch basin jetting as well as spill dilution and clean-up. Available in either a 375-gallon or 750-gallon water tank configuration, operators will find the all-new VecJet trailer offering not only an economical option, but a powerful and productive unit.

The All-New Vac-Con Jetter Series VJ375 and VJ750 are designed to take on the toughest sewer lines, storm drains and catch basins in a portable trailer-mounted configuration. This new low-profile design features the same power and portability for which Vac-Con trailer-mounted units are known. Applications include sewer line, storm drain, and catch basin jetting as well as spill dilution and clean-up. Available in either a 375-gallon or 750-gallon water tank configuration, operators will find the all-new VecJet trailer offering not only an economical option, but a powerful and productive unit. -

Innovation Adds Value, Safety and Ease of Maintenance

The New Way® Viper™ Rear Loader is one of the most popular mid-compaction rear loader bodies on the market today. Larger capacity Viper units are excellent for both residential and commercial work. New Way's engineering team has increased safety and added value with a design that moves the cylinders and the operating valve to the outside of the truck body. This creates a straight line between levers and control rods, making maintenance quick and easy. The operator valve placement eliminates the need to reach into the truck body, increasing employee safety. And, the Viper also comes standard with automatic tailgate locks with the control handle located on the side of the chassis; eliminating the time and effort needed to go back and forth to operate the traditional turnbuckle locks. With accessories and adapters to accommodate all varieties of residential cart tippers and commercial containers, a rear-view camera and a two-year cylinder warranty, this venomous rear loader is sure to paralyze the competition. -

If you occasionally have to set up off the road or any distance from the inspection vehicle, you simply must have an upper deflection pulley. This pulley converts the lateral force exerted onto the cable, turning into vertical force which allows your synchronized KW 305 or KW 505 to operate effectively. This simple attachment protects the cable, reduces the strain on the entire system, and helps you travel greater distances in the pipeline!

If you occasionally have to set up off the road or any distance from the inspection vehicle, you simply must have an upper deflection pulley. This pulley converts the lateral force exerted onto the cable, turning into vertical force which allows your synchronized KW 305 or KW 505 to operate effectively. This simple attachment protects the cable, reduces the strain on the entire system, and helps you travel greater distances in the pipeline! -

Vac-Con®'s Hot Shot high-pressure water jet machines are ideal for removing stones, bottles, cans, grease, sludge, and other debris from sanitary sewer and/or storm drain lines by the flushing action of high-pressure water. Hot Shot machines are equipped with a self contained, non-corrosive, non-metallic water tank and can be operated by one man, with all operating controls for high-pressure water, hose reel, located at the front of the machine for ease of operation and more safety.

Vac-Con®'s Hot Shot high-pressure water jet machines are ideal for removing stones, bottles, cans, grease, sludge, and other debris from sanitary sewer and/or storm drain lines by the flushing action of high-pressure water. Hot Shot machines are equipped with a self contained, non-corrosive, non-metallic water tank and can be operated by one man, with all operating controls for high-pressure water, hose reel, located at the front of the machine for ease of operation and more safety. -

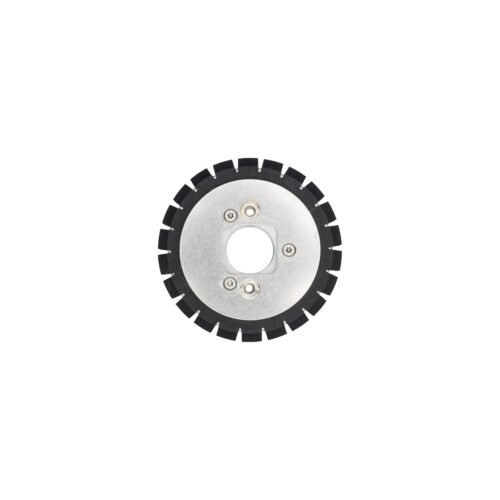

Available in two different composites, these wheels are perfect for climbing over rocks and debris. Profiled to maximize pipeline contact area, these high performance wheels provide extra grip in loose gravel and give you an edge when climbing up offset pipeline joints. Available in hard (black) or softer (brown) composites for any application.

Available in two different composites, these wheels are perfect for climbing over rocks and debris. Profiled to maximize pipeline contact area, these high performance wheels provide extra grip in loose gravel and give you an edge when climbing up offset pipeline joints. Available in hard (black) or softer (brown) composites for any application. -

Vac•Con®, in cooperation with Vector Technologies Ltd, is proud to introduce the VecJet™ line of powerful, yet compact, trailer-mounted jetter machines. These machines have a high-pressure water jet system with a Vac•Con hose reel. The VecJet is designed & manufactured for Vac•Con, adding the power of portability to an impressive line of truck-mounted combination machines, excavators and industrial machines - all accessible through the extensive Vac•Con dealer network. The VecJet provides the same rugged construction, quality and field-tested durability that both Vac•Con and Vector owners have relied upon for over three decades! The VecJet can be configured to meet your specific demanding requirements.

Vac•Con®, in cooperation with Vector Technologies Ltd, is proud to introduce the VecJet™ line of powerful, yet compact, trailer-mounted jetter machines. These machines have a high-pressure water jet system with a Vac•Con hose reel. The VecJet is designed & manufactured for Vac•Con, adding the power of portability to an impressive line of truck-mounted combination machines, excavators and industrial machines - all accessible through the extensive Vac•Con dealer network. The VecJet provides the same rugged construction, quality and field-tested durability that both Vac•Con and Vector owners have relied upon for over three decades! The VecJet can be configured to meet your specific demanding requirements. -

Titan Truck Single Engine Combination Machine

Vac-Con uses the simplicity of a hydrostatic drive to power both the vacuum and water systems with a single engine. Both systems can be independently operated for multiple applications, while allowing for maximum flexibility. Looking for a single-engine machine? Vac-Con’s unique design offers the best value without sacrificing performance, power or ease of operation. Available in:- 5 Yard Combination Sewer Cleaner

- 9 Yard Combination Sewer Cleaner

- 11 Yard Combination Sewer Cleaner

- 12 Yard Combination Sewer Cleaner

- 16 Yard Combination Sewer Cleaner

-

Titan Truck Dual Engine Combination Machine

Only Vac-Con combines the flexibility of a two-engine design to get the toughest jobs done right. Our efficient design, allowing the chassis engine to drive either the 3-stage fan or positive displacement blower vacuum system, actually saves you fuel and general wear and tear in the long run. Using a standard hydrostatic drive, this design can engage the industry’s most powerful vacuum. Offering a wide array of options, this is truly a “go anywhere, do anything” machine. Available in:- 5 Yard Combination Sewer Cleaner

- 9 Yard Combination Sewer Cleaner

- 11 Yard Combination Sewer Cleaner

- 12 Yard Combination Sewer Cleaner

- 16 Yard Combination Sewer Cleaner

-

Titan Truck

The premier Titan Combination Machine provides operators with the performance and power they’ve been asking for. This redesigned model was designed, tested, and built by the sewer cleaning experts at Vac-Con with feedback from our operators in the field. Our latest Titan model offers a wider range of size configurations including single and tandem axle options. But never fear, the Titan still boasts these impressive characteristics:- 44% Fuel Savings

- 43% Decrease in Vacuum System Operating RPM

- 25% Increase in Airflow

- 20% More Horsepower

- 8% Decrease in Noise Pollution

- 5% Increase in Overall Vacuum Pressure (Lift)

- 10 Yard Combination Sewer Cleaner

- 12 Yard Combination Sewer Cleaner

-

The much-anticipated Vac•Con® Recycler is here, and it is worth the wait! Designed from proven European technology and the durability to keep you on the job working longer, the Vac-Con Recycler has already made its mark on the industry. The combination machine you trust is now available with the recycling system you need for endurance and performance. The Vac-Con Recycler boasts features to provide operators with functional flexibility saving you time, increasing efficiency, and getting the job done.

The much-anticipated Vac•Con® Recycler is here, and it is worth the wait! Designed from proven European technology and the durability to keep you on the job working longer, the Vac-Con Recycler has already made its mark on the industry. The combination machine you trust is now available with the recycling system you need for endurance and performance. The Vac-Con Recycler boasts features to provide operators with functional flexibility saving you time, increasing efficiency, and getting the job done. -

The T86 is the high power cousin to the T76. By trading steerability for a single, more powerful motor, you are able to operate this tractor in the most demanding environments. Heavier, providing greater traction, the T86 is capable of pulling out more cable and traversing larger amounts of debris in the sewer. Perfect for storm lines or any large diameter pipeline! Includes an integrated transmitter for location above ground interchangeable between two different frequencies (33 khz and 512 Hz). Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation HD Support Available: contact a member of the sales team for more information!

The T86 is the high power cousin to the T76. By trading steerability for a single, more powerful motor, you are able to operate this tractor in the most demanding environments. Heavier, providing greater traction, the T86 is capable of pulling out more cable and traversing larger amounts of debris in the sewer. Perfect for storm lines or any large diameter pipeline! Includes an integrated transmitter for location above ground interchangeable between two different frequencies (33 khz and 512 Hz). Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation HD Support Available: contact a member of the sales team for more information! -

This large attachment adds considerable height and weight to the system. This makes sure you are up out of the water while maintaining a low center of gravity. The large attachment includes additional weight which hangs below the carriage. The large attachment is the same for both the T76 and T86 tractors, but require different mounting brackets.

This large attachment adds considerable height and weight to the system. This makes sure you are up out of the water while maintaining a low center of gravity. The large attachment includes additional weight which hangs below the carriage. The large attachment is the same for both the T76 and T86 tractors, but require different mounting brackets. -

The T76 has the broadest range of any sewer inspection robot. This system which will inspect relined 6” sewer pipe, easily transforms into a tractor capable of inspecting large diameter pipelines. The new T76 is the first inspection crawler capable of accepting a LISY Lateral Launch system attachment, turning it into a complete mainline and lateral launch solution! Features include zero radius steering, continuous camera rotation, automatic tilt compensation, and a folding 2-axis rear connector. Our tractors are also equipped with a location transmitter that puts out two different frequencies (33 khz and 512 Hz) to cooperate with your job conditions. The hooks attached to the side of our tractors allow for easy raising/lowering. Accessories include remote elevators for lifting the camera above the water line and inclinometers for testing the slope of the pipeline. Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation 🎦 Automatic Tilt Compensation (ATC) HD Support Available: contact a member of the sales team for more information!

The T76 has the broadest range of any sewer inspection robot. This system which will inspect relined 6” sewer pipe, easily transforms into a tractor capable of inspecting large diameter pipelines. The new T76 is the first inspection crawler capable of accepting a LISY Lateral Launch system attachment, turning it into a complete mainline and lateral launch solution! Features include zero radius steering, continuous camera rotation, automatic tilt compensation, and a folding 2-axis rear connector. Our tractors are also equipped with a location transmitter that puts out two different frequencies (33 khz and 512 Hz) to cooperate with your job conditions. The hooks attached to the side of our tractors allow for easy raising/lowering. Accessories include remote elevators for lifting the camera above the water line and inclinometers for testing the slope of the pipeline. Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation 🎦 Automatic Tilt Compensation (ATC) HD Support Available: contact a member of the sales team for more information! -

The T66 Steerable Camera Tractor is the latest in the long line of innovative sewer camera transporters from IBAK. This tractor includes continuous camera rotation, automatic tilt compensation, and a steerable drive shaft. The T66 boasts a heavier chassis for added traction, smaller external dimensions for ease of use and greater pulling strength than its predecessor. Small and agile, yet more powerful than some pipe inspection crawlers twice its size – the T66 is the core of an effective inspection system for sewers and pipelines ranging from 4” to over 24” in diameter. With patented hooks attached to the sides of our tractors, raising and lowering has never been more effortless! Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation 🎦 Automatic Tilt Compensation (ATC) HD Support Available: contact a member of the sales team for more information!

The T66 Steerable Camera Tractor is the latest in the long line of innovative sewer camera transporters from IBAK. This tractor includes continuous camera rotation, automatic tilt compensation, and a steerable drive shaft. The T66 boasts a heavier chassis for added traction, smaller external dimensions for ease of use and greater pulling strength than its predecessor. Small and agile, yet more powerful than some pipe inspection crawlers twice its size – the T66 is the core of an effective inspection system for sewers and pipelines ranging from 4” to over 24” in diameter. With patented hooks attached to the sides of our tractors, raising and lowering has never been more effortless! Highlighted Features: 🎦 Internal Strain Relief 🎦 Air Pressurization/Regulation 🎦 Automatic Tilt Compensation (ATC) HD Support Available: contact a member of the sales team for more information! -

One Operator Efficiency

Efficiency is always at your side with the New Way® Sidewinder XTR™ Automated Side Loader. With a faster compaction rate unrivaled by any other side loader on the market and the industry's strongest frame-mounted arm that reaches an impressive 12 feet, efficiency is always at your side. The Sidewinder combines the convenience of automated loading with the ability to maneuver in tight spaces to create an ultra-tough, overbuilt side loading machine. At the end of the day, the convenient features of the Sidewinder XTR are even more evident. Operators appreciate the convenience of being able to easily clean out behind the RAM with the widest opening access and largest clean-out sump in the industry. Add to that the standard rear-view camera and a two-year cylinder warranty, and you can see why the Sidewinder XTR has a solid grip on the competition. -

Roto Pac

The future goal of waste management is zero waste being deposited into landfills. With an eye toward that future, New Way® leads the industry with the introduction of the first auger-driven organics collection truck in North America, the ROTO PAC®. Organics on Monday, municipal solid waste (MSW) on Tuesday. Gone are the days of maintaining separate trucks to meet a community's waste management needs. As the first refuse truck that works as equally well with MSW as it does with organics refuse collection, the dual purpose ROTO PAC® is designed for operational flexibility. The ROTO PAC®'s self-cleaning auger not only more efficiently compacts organic materials, such as grass clipping and food waste, but will automatically reverse in the event of a jam. The 23,000 lbs of auger torque makes quick work of compaction and self-cleaning, eliminating down time to clean out behind the packer RAM. The automated arm has a 12-foot reach and can easily manage up to 500 lbs at maximum extension. Add to that a 27 yd³ body, the highest legal payload in the industry of 25,000 lbs, reduced cylinder maintenance because of the auger and a liquid-tight hopper up to 40 inches high, and you have the most innovative, adaptable and futuristic refuse truck available on the market today. -

Most of our systems are synchronized to make sure that you do not back over your cable while retrieving, but occasionally it is helpful to have a rear-facing view when returning to the manhole. The RETRUS HD automatically changes your view in full digital HD resolution when the system is reversed allowing you to avoid dangers on the return trip.

Most of our systems are synchronized to make sure that you do not back over your cable while retrieving, but occasionally it is helpful to have a rear-facing view when returning to the manhole. The RETRUS HD automatically changes your view in full digital HD resolution when the system is reversed allowing you to avoid dangers on the return trip. -

This package contains all the inspection equipment you need to conduct video inspections in 6” (125mm) pipe to over 48” (1200mm) pipe. You will be able to conduct inspections with more speed and accuracy with this powerful synchronized KW 305 cable reel, 1000’ (300m) capability, larger and more powerful T76 tractor, and ORPHEUS 2.0 camera, and operating it all with the BS3.5 Control Center. The built-in cable winch lowers the tractor into the manhole, reducing stress on personnel and helps prevent damage and injury. Related Videos: 🎦 ORPHEUS 2.0 and ORPHEUS 2.0 HD Overview 🎦 T76 Tractor Overview 🎦 Fully Synchronized Cable Reels

This package contains all the inspection equipment you need to conduct video inspections in 6” (125mm) pipe to over 48” (1200mm) pipe. You will be able to conduct inspections with more speed and accuracy with this powerful synchronized KW 305 cable reel, 1000’ (300m) capability, larger and more powerful T76 tractor, and ORPHEUS 2.0 camera, and operating it all with the BS3.5 Control Center. The built-in cable winch lowers the tractor into the manhole, reducing stress on personnel and helps prevent damage and injury. Related Videos: 🎦 ORPHEUS 2.0 and ORPHEUS 2.0 HD Overview 🎦 T76 Tractor Overview 🎦 Fully Synchronized Cable Reels -

Enter the high-definition era with this premium HD sewer camera system that has the equipment you need to conduct digital HD inspections in 6″ diameter and larger pipelines. The new ORPHEUS 2.0 HD camera delivers exciting new features and incredible digital HD picture clarity, all while delivering enough clean, bright LED light to illuminate huge areas. The T76 HD tractor is our most powerful steerable tractor with capabilities in the largest lines with accessories, and the powerful camera lighting of the OPRHEUS 2.0 HD can illuminate up to 120″ diameter pipelines with ease. Related Videos: 🎦 IBAK HD Camera Footage ORPHEUS 2.0 HD + ORION 3 🎦 ORPHEUS 2.0 and ORPHEUS 2.0 HD Overview 🎦 T76 Tractor Overview 🎦 Fully Synchronized Cable Reels

Enter the high-definition era with this premium HD sewer camera system that has the equipment you need to conduct digital HD inspections in 6″ diameter and larger pipelines. The new ORPHEUS 2.0 HD camera delivers exciting new features and incredible digital HD picture clarity, all while delivering enough clean, bright LED light to illuminate huge areas. The T76 HD tractor is our most powerful steerable tractor with capabilities in the largest lines with accessories, and the powerful camera lighting of the OPRHEUS 2.0 HD can illuminate up to 120″ diameter pipelines with ease. Related Videos: 🎦 IBAK HD Camera Footage ORPHEUS 2.0 HD + ORION 3 🎦 ORPHEUS 2.0 and ORPHEUS 2.0 HD Overview 🎦 T76 Tractor Overview 🎦 Fully Synchronized Cable Reels -

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels.

These air-filled tires are great all-purpose tires for use in larger diameter pipes. Use them to climb over obstacles and power through silt and debris. Pneumatic tires are available in multiple sizes for all of our tractors. If you inspect large diameter pipeline, you cannot afford to overlook these wheels. -

This attachment allows you to turn your LISY lateral launch system into a lateral cleaning unit. The PHOBOS nozzle propels the pushrod up into the lateral from the LISY unit, cleaning while it goes. The nozzle not only cleans, but increases the distance possible by providing more thrust. The lateral cleaning attachment is quick and easy to install, and can be used in conjunction with the large diameter kits to clean laterals in larger pipelines. If you are a contractor, you can use this accessory to add a unique service to your offering. If you are a municipality who is responsible for the laterals in your community, why not clean them as you inspect?

This attachment allows you to turn your LISY lateral launch system into a lateral cleaning unit. The PHOBOS nozzle propels the pushrod up into the lateral from the LISY unit, cleaning while it goes. The nozzle not only cleans, but increases the distance possible by providing more thrust. The lateral cleaning attachment is quick and easy to install, and can be used in conjunction with the large diameter kits to clean laterals in larger pipelines. If you are a contractor, you can use this accessory to add a unique service to your offering. If you are a municipality who is responsible for the laterals in your community, why not clean them as you inspect? -

No other system captures the quality or quantity of data that the PANORAMO® SI 4K does. It’s unique ability to capture every inch of the manhole ensures you never miss an observation. The PANORAMO® SI 4K can be used as an add-on to your existing PANORAMO® system, or can be used as a portable stand-alone unit with our new KW SI Cable Reel. This newly designed cable reel can be operated from the mobile rack with a laptop, or it can be installed in a vehicle. The quick-acting fasteners allow the cable reel and mobile rack to be removed from the vehicle and converted into a mobile system in a few easy steps. All of the components of the system are intended for outdoor use, from the large pneumatic tires to the water-resistant laptop. Power is supplied from high-efficiency standard rechargeable batteries or a lithium battery installed in your vehicle.

No other system captures the quality or quantity of data that the PANORAMO® SI 4K does. It’s unique ability to capture every inch of the manhole ensures you never miss an observation. The PANORAMO® SI 4K can be used as an add-on to your existing PANORAMO® system, or can be used as a portable stand-alone unit with our new KW SI Cable Reel. This newly designed cable reel can be operated from the mobile rack with a laptop, or it can be installed in a vehicle. The quick-acting fasteners allow the cable reel and mobile rack to be removed from the vehicle and converted into a mobile system in a few easy steps. All of the components of the system are intended for outdoor use, from the large pneumatic tires to the water-resistant laptop. Power is supplied from high-efficiency standard rechargeable batteries or a lithium battery installed in your vehicle. -

No other system captures the quality or quantity of data that PANORAMO SI 4K does. Other 3D optical manhole scanners are slow, clumsy, and unsafe & we all know how much of a pain using a pole camera for sewer inspection can be. With its unique ability to capture every inch of the manhole, you will never miss an observation. Keep your employees safe, increase the productivity and accuracy of your crews and provide clear data that helps system owners make informed decisions. The PANORAMO® SI can be used as an add-on to your existing PANORAMO® system or can be used as a portable stand-alone unit. Completely self-contained system on a 4′ x 4′ skid that can easily be mounted in a cargo van, pick-up bed, or an off road ATV. The electronics are mounted in a shock-resistant military style case with a flip-up monitor and keyboard. Related Products: PANORAMO® SI 4K Mobile Configuration

No other system captures the quality or quantity of data that PANORAMO SI 4K does. Other 3D optical manhole scanners are slow, clumsy, and unsafe & we all know how much of a pain using a pole camera for sewer inspection can be. With its unique ability to capture every inch of the manhole, you will never miss an observation. Keep your employees safe, increase the productivity and accuracy of your crews and provide clear data that helps system owners make informed decisions. The PANORAMO® SI can be used as an add-on to your existing PANORAMO® system or can be used as a portable stand-alone unit. Completely self-contained system on a 4′ x 4′ skid that can easily be mounted in a cargo van, pick-up bed, or an off road ATV. The electronics are mounted in a shock-resistant military style case with a flip-up monitor and keyboard. Related Products: PANORAMO® SI 4K Mobile Configuration -

The PANORAMO® 3D optical scanning package is the latest in inspection technologies, and has changed the way that both pipelines and manholes are inspected. This package will allow you to inspect 3 to 5 times the amount of pipe per day as a traditional analog inspection system (also spending less time in busy intersections!) while providing amazing image clarity and astonishing deliverable. It’s capable of inspecting anything from storm water pipe to sanitary lines. The dual digital cameras produce images with up to 3,000 lines of resolution and provides an un-folded view of the pipeline. This package also features the virtual pan & tilt mode that allows anyone to inspect the pipe from the comfort of their office as if they were sitting in the camera truck. Everything you need to improve your inspection speed and increase your profits is included in this package. Package includes: PANORAMO® 360° Camera System, Electronic Lift, Inclinometer, KW 505 Fiber Optic Reel with 1640’ of cable, BE 7 controller, PANORAMO® PCI Card, Downhole Rollers and a Pressure Test Set.

The PANORAMO® 3D optical scanning package is the latest in inspection technologies, and has changed the way that both pipelines and manholes are inspected. This package will allow you to inspect 3 to 5 times the amount of pipe per day as a traditional analog inspection system (also spending less time in busy intersections!) while providing amazing image clarity and astonishing deliverable. It’s capable of inspecting anything from storm water pipe to sanitary lines. The dual digital cameras produce images with up to 3,000 lines of resolution and provides an un-folded view of the pipeline. This package also features the virtual pan & tilt mode that allows anyone to inspect the pipe from the comfort of their office as if they were sitting in the camera truck. Everything you need to improve your inspection speed and increase your profits is included in this package. Package includes: PANORAMO® 360° Camera System, Electronic Lift, Inclinometer, KW 505 Fiber Optic Reel with 1640’ of cable, BE 7 controller, PANORAMO® PCI Card, Downhole Rollers and a Pressure Test Set. -

IBAK designed PANORAMO® from the ground up to address the weaknesses of traditional sewer inspection technology. The PANORAMO® method changes your current process into data collection in the field and data analysis back in the office. The technology enables your employees to work to their potential and avoid costly mistakes caused by inattention or stress. At the core of the PANORAMO® system are the wide angle (185º) twin digital cameras. These cameras are installed on the front and rear of the system and capture still images as they move through the pipeline. Extremely powerful Xenon strobes illuminate up to 48” pipelines, and the still pictures captured by the cameras produce high-resolution digital images that do not suffer from motion blur even at the highest inspection speeds. The PANORAMO® system has very few moving parts, allowing for easier maintenance than that of traditional pan & tilt cameras. Over the past few years, the PANORAMO® product line has been further improved on the basis of its well proven technology. The result is an even much more brilliant picture with 4K resolution. The abbreviation 4K stands for 4000 and means the approximate number of horizontal picture elements (4096 × 2160 pixels). So this means that the resolution is four times greater than full HD. To achieve such brilliance and to allow this high resolution to be displayed on the monitor and stored, the transmission path has been revolutionized. For the first time in the history of IBAK, a Gigabit Ethernet Standard is being used for the transmission of images and other data. IBAK has very positive experience in the implementation of fiber-optic technology. With the Gigabit Ethernet Standard, a data transmission rate of up to a billion bits (one gigabit) per second is possible. In the new PANORAMO® generation, as with most other IBAK cameras, there will be the option of integrating a 3D sensor for pipe run measurement.

IBAK designed PANORAMO® from the ground up to address the weaknesses of traditional sewer inspection technology. The PANORAMO® method changes your current process into data collection in the field and data analysis back in the office. The technology enables your employees to work to their potential and avoid costly mistakes caused by inattention or stress. At the core of the PANORAMO® system are the wide angle (185º) twin digital cameras. These cameras are installed on the front and rear of the system and capture still images as they move through the pipeline. Extremely powerful Xenon strobes illuminate up to 48” pipelines, and the still pictures captured by the cameras produce high-resolution digital images that do not suffer from motion blur even at the highest inspection speeds. The PANORAMO® system has very few moving parts, allowing for easier maintenance than that of traditional pan & tilt cameras. Over the past few years, the PANORAMO® product line has been further improved on the basis of its well proven technology. The result is an even much more brilliant picture with 4K resolution. The abbreviation 4K stands for 4000 and means the approximate number of horizontal picture elements (4096 × 2160 pixels). So this means that the resolution is four times greater than full HD. To achieve such brilliance and to allow this high resolution to be displayed on the monitor and stored, the transmission path has been revolutionized. For the first time in the history of IBAK, a Gigabit Ethernet Standard is being used for the transmission of images and other data. IBAK has very positive experience in the implementation of fiber-optic technology. With the Gigabit Ethernet Standard, a data transmission rate of up to a billion bits (one gigabit) per second is possible. In the new PANORAMO® generation, as with most other IBAK cameras, there will be the option of integrating a 3D sensor for pipe run measurement.